“Three-Dimensional (3D) Laser-Induced Graphene: Structure, Properties, and Application to Chemical Sensing“

Federico Maria Vivaldi, Alexander Dallinger, Andrea Bonini, Noemi Poma, Lorenzo Sembranti, Denise Biagini, Pietro Salvo, Francesco Greco*, and Fabio Di Francesco*

Publication Date: June 24, 2021

https://pubs.acs.org/doi/10.1021/acsami.1c05614

Abstract

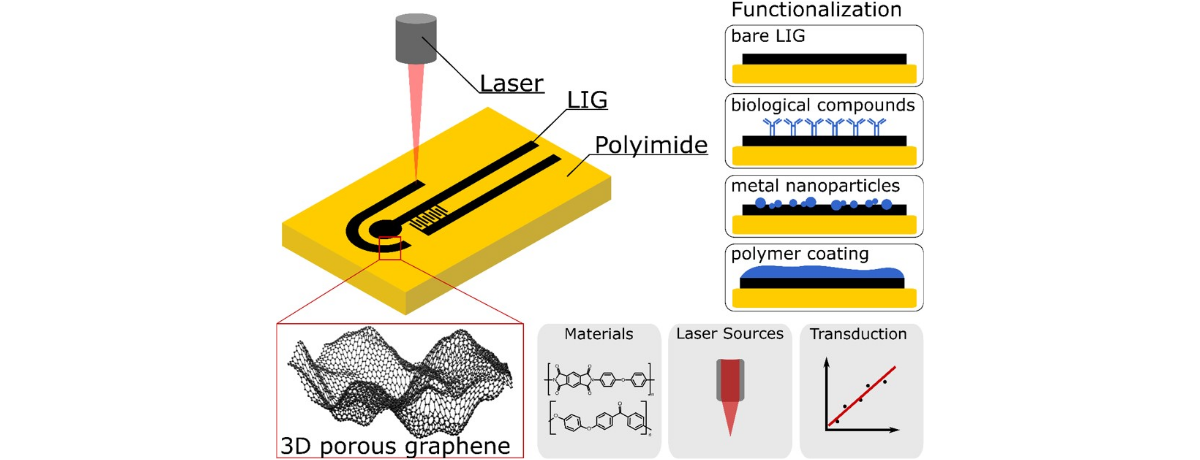

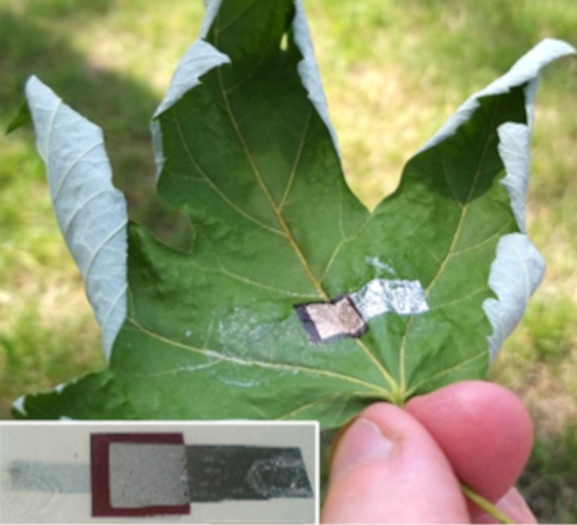

Notwithstanding its relatively recent discovery, graphene has gone through many evolution steps and inspired a multitude of applications in many fields, from electronics to life science. The recent advancements in graphene production and patterning, and the inclusion of two-dimensional (2D) graphenic materials in three-dimensional (3D) superstructures, further extended the number of potential applications. In this Review, we focus on laser-induced graphene (LIG), an intriguing 3D porous graphenic material produced by direct laser scribing of carbonaceous precursors, and on its applications in chemical sensors and biosensors. LIG can be shaped in different 3D forms with a high surface-to-volume ratio, which is a valuable characteristic for sensors that typically rely on phenomena occurring at surfaces and interfaces. Herein, an overview of LIG, including synthesis from various precursors, structure, and characteristic properties, is first provided. The discussion focuses especially on transport and surface properties, and on how these can be controlled by tuning the laser processing. Progresses and trends in LIG-based chemical sensors are then reviewed, discussing the various transduction mechanisms and different LIG functionalization procedures for chemical sensing. A comparative evaluation of sensors performance is then provided. Finally, sensors for glucose detection are reviewed in more detail, since they represent the vast majority of LIG-based chemical sensors.