LAMPSe is contributing to the EU FET-open 5D NanoPrinting project which started in September 2020 and has a duration of 4 years.

The team of LAMPSe participating in this project is composed by Francesco Greco and Alexander Dallinger. Alexander Dallinger will investigate methods for creating conformal conductive paths based on Laser Induced Graphene (LIG).

Another partner in the consortium at TU Graz is the group of Anna Maria Coclite, who will be investigating Stimuli Responsive Materials for Sensing.

The Project Idea

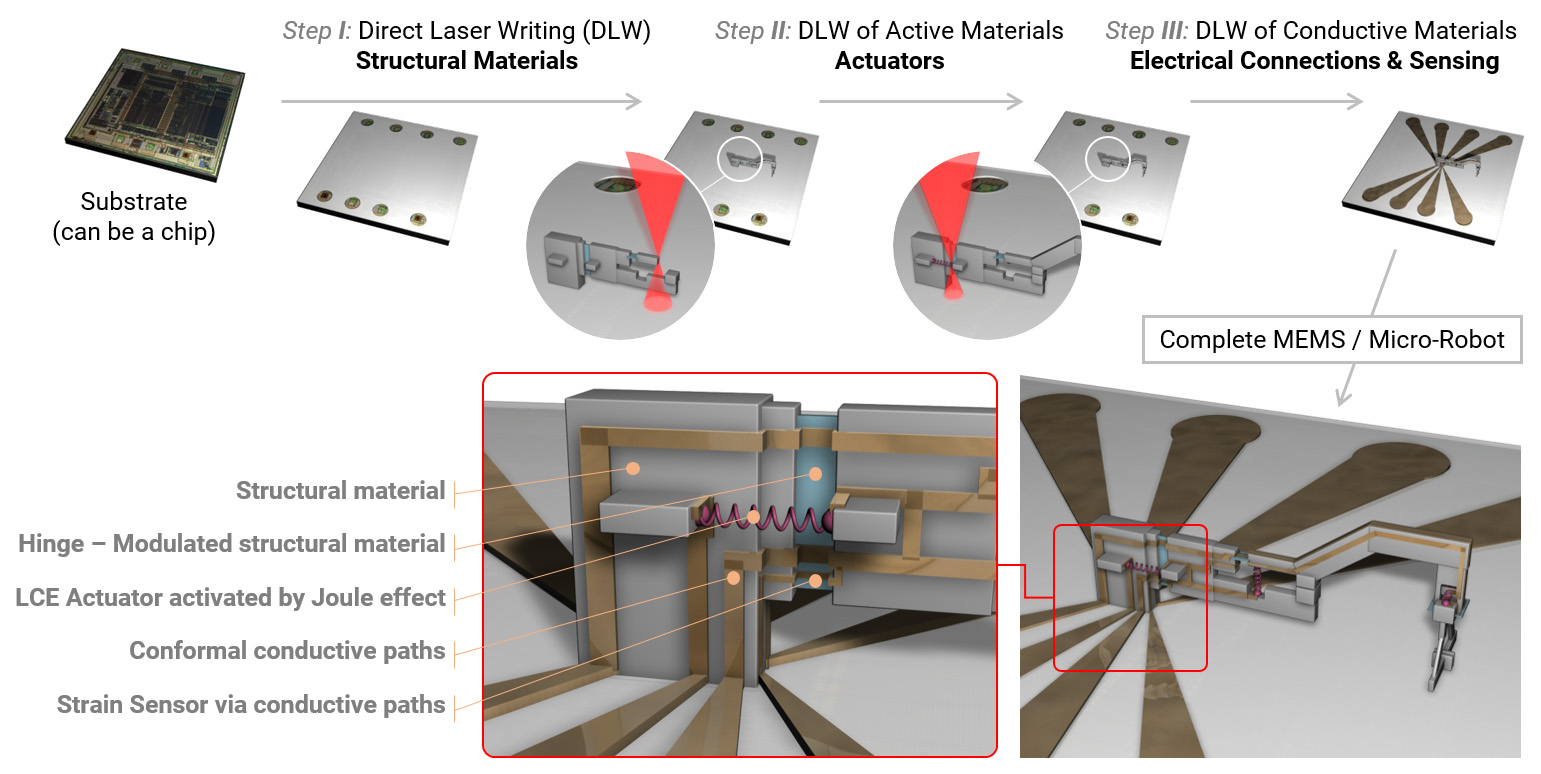

The 5D NanoPrinting EU FET-open project aims to set a new paradigm in the 3D printing technology of micro and nano machines through Direct Laser Writing via two-photons polymerization processes.

By developing innovative smart/functional materials with tailorable properties and novel fabrication methodologies, it aims to propel forward the current state-of-the-art micro(nano)printing technologies, allowing faster prototyping and designing of micro-electromechanical systems (MEMS).

What are Micro Machines?

The term ‘micromachines’ – also known as ‘Micro ElectroMechanical Systems’ (MEMS) – refers to microscopic devices with moving parts (usually between 1 micrometer and 1 millimeter long), which are capable of performing a specific task. Such technology is widely diffuse, finding applications that spans from the automotive industry, consumer electronics, and healthcare. The MEMS market share was estimated to be around 50 billion US$ in 2018, and rapidly growing.

5D NanoPrinting objectives

Despite the progress made in the fabrication of MEMS in the last decade, the technology currently employed does not allow them to reach their full potential. Limitations in the materials and the fabrications methodologies, as well as the long and expensive development process that many devices need, are hindering the full development of this technology, slowing down the access to the market and increasing prices.

The 5DNanoPrint approach aims to overcome these issues by developing new fabrication strategies based on direct 3D printing at the micron scale via two-photons polymerization processes. Such technique, known as Direct Laser Writing (DLW), consists in the use of focused laser pulses to print the microstructures with extremely high resolution, complexity, and throughput, thus bringing the advantages of the 3D-printing as we know it down to the micrometer dimension.

5D NanoPrinting action

The researchers involved in the project will combine synthetic and nano-technological approaches to develop innovative performant materials for DLW characterized by specific functionalities, such as responsiveness to light, temperature, and electric fields, the ability to conduct electricity, or dynamic change of their mechanical properties. These functionalities can allow the dynamic control of the micromachine behavior in real time, thus adding ‘two extra dimensions’ (i.e. function and time) to the standard 3D-printed microstructures.

In addition, the inherent fast prototyping allowed by DLW compared to the other lithographic approaches currently in use, can speed up the developing of novel technologies, both during research and production.

These breakthroughs will set a new golden standard for the production of customizable complex 3D microstructures and machines. In the future that will benefit those applications where high precision and reliability must meet the small dimensions, such as in minimally invasive implants for medical applications, development of microrobots, and fabrication of more advanced components for consumer electronics.

5DNanoPrinting is a European project funded under the Future and Emerging Technologies (FET) programme, specifically FET-Open, of the EU framework programme for research and innovation (Horizon 2020).