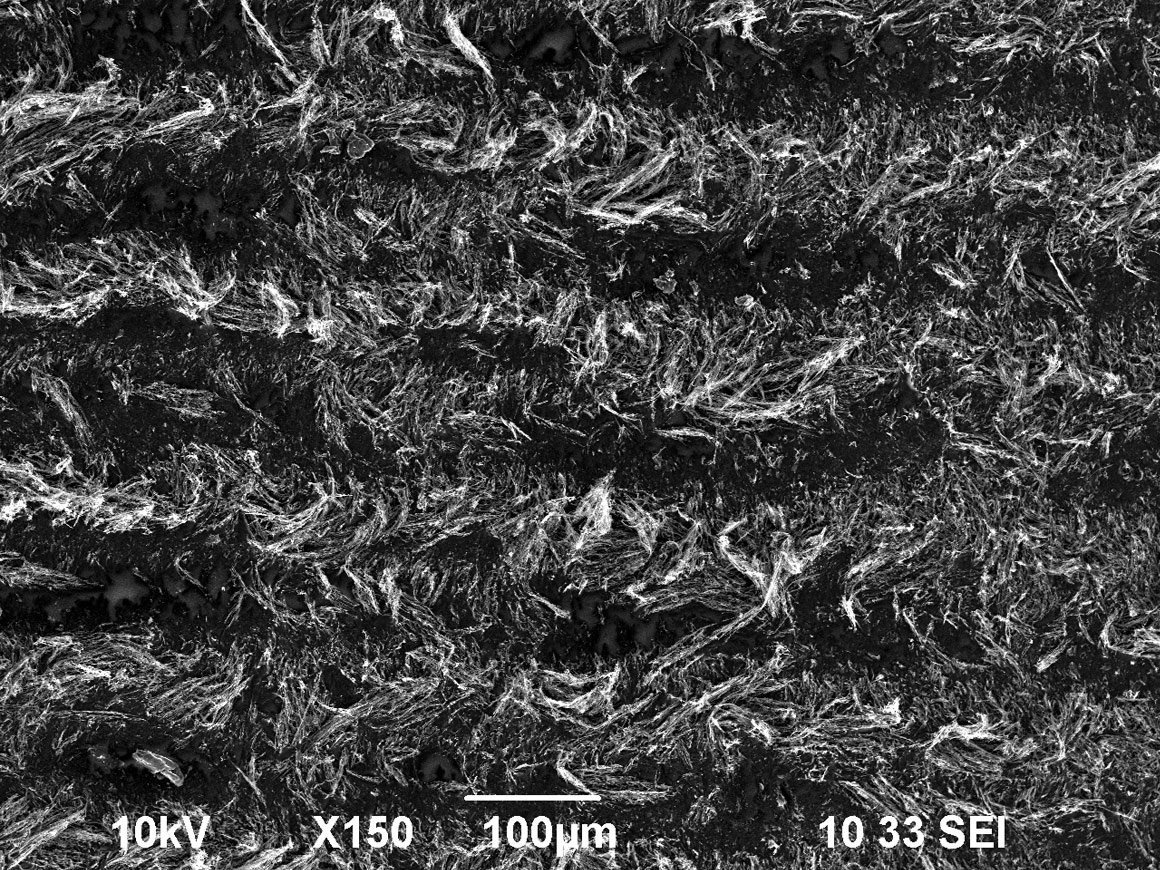

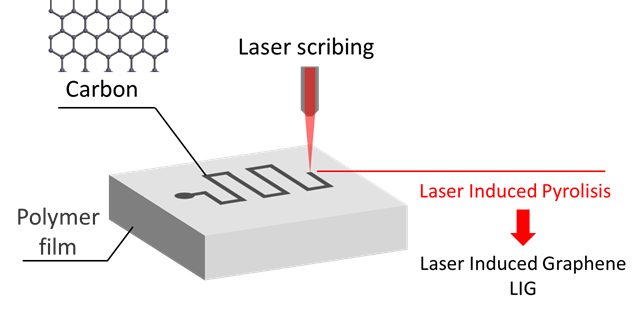

A fairly new method to produce 3D nanoporous graphene, first discovered and investigated by Lin et al., utilized commercially available CO2 laser sources to convert insulating Polyimide (PI) into conductive so-called Laser Induced Graphene (LIG).1

This process benefits from the absence of any chemicals, no need for inert atmospheres, and the possibility of converting insulating into conductive material in an controlled and localized way. Over the years the research interest has grown and up to date a lot of different devices based on LIG have been shown. One of the first devices demonstrated was a microsupercapacitor fabricated from PI. Followed by stackable supercapacitors and stretchable supercapacitors.

Other LIG based devices such as acoustic sensors, strain sensor, gas sensors, electrophysiological sensors and electrochemical sensors have been demonstrated.

- Lin, J. et al. Laser-induced porous graphene films from commercial polymers. Nature communications 5, 5714 (2014).

Investigations @ LAMPSe

- Theoretical calculation of deposited laser fluence

- Influence of laser fluence on physical properties (e.g. conductivity)

- Alternative Precursors (renewable, bioderived)

- Surface modification with LIG (e.g. superhydrophobicity)

- Application of LIG:

- Physical Sensor

- Biosensors

- Actuators

- Bioinspired Surfaces

- Stretchable Conductors

- Supercapacitors